Positive displacement flowmeter-PD Meters

When it comes to measuring the overall volumetric flow rates for liquid matter, nothing works better than flow meters that are used in varied applications pertaining to different operational fields. Positive displacement flowmeter present in the market are used for several high-end applications, and each of them possesses different advantages, functional values, features, mechanisms, and specifications.

Positive displacement Flow meters are the types of flowmeters which are suitable for measurement of viscous liquid flows. These are also considered ideal for applications which require the use of a simple mechanical meter system. In general, a positive displacement flow meter consists of a chamber or cavity which restricts the flow. A rotating or reciprocating mechanical device is located inside the chamber to generate fixed-volume discrete parcels from the flowing liquid. Via PD meter units, liquids get separated into exactly calculated increments which are then further counted by a connecting register. Since every measured increment represents a distinct volume, these types of meters are widely used for automatic batching and accounting purposes.

What is a Positive Displacement Flow Meter?

To define the device, what is Positive Displacement flow meter (PD) ? – A mechanical meter that is best used for non-corrosive and clean mediums. Being capable of measuring an extensive range of fluids that include even the ones with high viscosities, this flow meter comes with several advantages.

Also known as workhorses in flow measurement applications, this flow rate measurement device measures the flow rate of a liquid substance by letting it to move through a system in installments. When utilized for industrial applications, PD flow meters are known for their capabilities to measure multiple intricate and critical liquid flow rates with accuracy and ease.

Positive Displacement (PD) Flow meters are volumetric flow measurement instruments that measure flow by passing a precise volume of fluid with each revolution. PD flow meters are precision instruments whose internal moving components are hydraulically locked in tandem with the volume of fluid moving through the flow meter.

Positive Displacement Meter is a type of flow meter that requires fluid to mechanically displace components in the meter in order for flow measurement. Positive displacement (PD) flow meters measure the volumetric flow rate of a moving fluid or gas by dividing the media into fixed, metered volumes (finite increments or volumes of the fluid).

How does a Positive Displacement Flow Meter Work?

A basic analogy would be holding a bucket below a tap, filling it to a set level, then quickly replacing it with another bucket and timing the rate at which the buckets are filled (or the total number of buckets for the “totalized” flow). With appropriate pressure and temperature compensation, the mass flow rate can be accurately determined.

Koeo M series meters are positive displacement meters. They are designed for liquid measurement in both custody-transfer and process-control applications. They can be installed in pump or gravity flow systems. Because of their simple design, they are easy to maintain, and easy to adapt to a variety of systems.

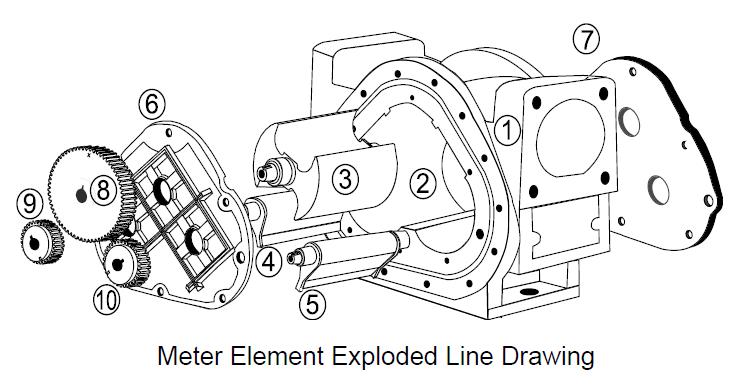

The meter housing (1) is designed with three cylindrical bores (2). Three rotors, the blocking rotor (3) and two displacement rotors (4, 5), turn in synchronized relationship within the bores. The three rotors are supported by bearing plates (6, 7). The ends of the rotors protrude through the bearing plates. The blocking rotor gear (8) is placed on the end of the blocking rotor. The displacement rotor gears (9, 10) are placed on the ends of the displacement rotors. These gears create the synchronized timed relationship between the three rotors.

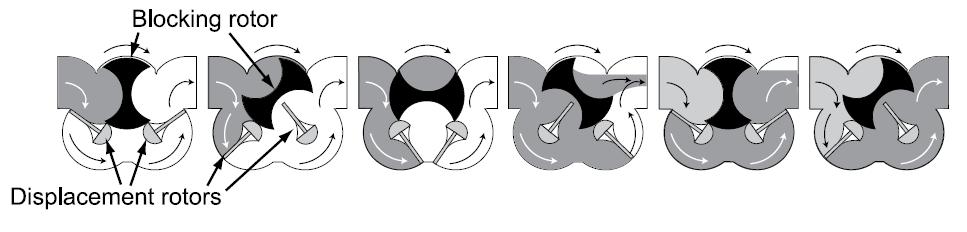

As fluid moves through the meter housing, the rotor assembly turns. The liquid is broken into uniform sections by the turning rotors. Fluid displacement occurs simultaneously. As fluid enters, another portion of the fluid is being partitioned and measured. At the same time, the fluid ahead of it is displaced out of the meter and into the discharge line. Since the volume of the bores is known, and the same amount of fluid passes through the meter during each revolution of the blocking rotor, the exact volume of liquid that has passed through the meter can be determined with a high degree of accuracy.

This true rotary motion is transmitted through the packing gland, the face gear, the adjuster drive shaft, and the adjuster to the register stack and counter. True rotary motion output means consistent accuracy, since the register indication is in precise agreement with the actual volume throughput at any given instant. At any position in the cycle, the meter body, the blocking rotor, and at least one of the displacement rotors form a continuous capillary seal between the unmetered upstream product and the metered downstream product.

Because the product is separated by the capillary seal, no metal-to-metal contact is required within the metering element. This means no wear, and no wear means no increase in slippage, which means no deterioration in accuracy.

Throughout the metering element, the mating surfaces are either flat surfaces or cylindrical faces and sections that are accurately machined. These relatively simple machining operations, plus the fact that there is no oscillating or reciprocating motion within the device, permits extremely close and consistent tolerances within the Koeo positive displacement meters.

The product flowing through the meter exerts a dynamic force that is at right angles to the faces of the displacement rotors. The meter is designed so that the rotor shafts are always in a horizontal plane. These two facts result in no axial thrust. Therefore, Koeo positive displacement meters do not need thrust washers or thrust bearings, and the rotors automatically seek the center of the stream between the two bearing plates–eliminating wear between the ends of the rotors and the bearing plates. Once again, no wear results mean no metal fatigue and no friction.

Koeo positive displacement meters are made of a variety of materials to suit a variety of products. Because of their no-wear design, capillary seals, and unique rotary metering, Koeo positive displacement meters provide unequalled accuracy, long operating life, and exceptional dependability.

Features and advantages.

• The positive displacement meters can measure intermittent flows, very low flow rates, and liquids of almost any viscosity. The PD meter instantly moves when there is fluid motion, and instantly stops when the fluid motion stops.

• The Measurement of positive displacement meter is not affected by the liquid’s viscosity, density or the turbulence in the pipe. All incompressible fluids will occupy the same volume and there is no need to correct the meter’s output to compensate for these factors.

• High accuracy

• Low pressure drops

• Stepless calibration adjustment

• Wear compensating vane design

• Mechanical or electronic readout

• Suitable for a wide variety of liquids

• Positive displacement type flowmeters usually offer high accuracy i.e. about ±0.1% of actual flow rate sometimes. The metering accuracy of the unit gets better with the increase in the process fluid viscosity.

• PD meters also provide excellent repeatability which can be as high as 0.05% of reading.

• PD meters can work without using a power supply. Moreover, they do not necessitate straight upstream and downstream pipe runs to install them.

• PD meters exist in size up to 12 in.

• Their turndown ratio can be as high as 100:1.

• Since PD meters have very small clearances between their precision-machined parts, rapid wear influences their accuracy. Therefore, these types of meters are normally not suggested for measurement of slurries or abrasive fluids.

• Positive displacement flowmeters are commonly employed as household water meters.

• The accuracy of positive displacement flowmeters depends upon the reliability of the capillary seal used to separate the passing liquid into discrete parcels. For getting the required accuracy and making sure that a PD meter works appropriately, a filtration system is needed. This filter system should be capable enough to remove large size particles as well as gas bubbles from the liquid flow.

• Positive displacement flowmeters work on a very simple operating principle. Positive displacement flowmeters consist of precision-fitted rotors for measurement of process fluid flow. Fixed volumes of liquid are moved between the rotors. The rotation of these rotors is directly proportional to the volume of the liquid being moved on.

• A central electronic pulse transmitter is included in a typical PD meter design which counts the number of rotations of the rotor. This counted number is then used to calculate liquid volume and flow rate.

• Rotor of a positive displacement type flowmeter can be constructed in numerous ways.

• Positive displacement flowmeters can be employed for nearly all nonabrasive fluids like heating oils, lubrication oils, polymer additives, animal and vegetable fat, printing ink, freon, etc..